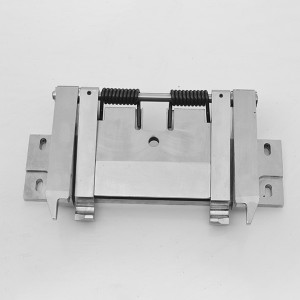

Stamping process

Kutsikirira (kunozivikanwawo sekudzvanya) maitiro ekuisa simbi yakatsetseka mune isina chinhu kana kuti coil fomu mumuchina wekutsikirira apo mudziyo nefafa pamusoro zvinoumba simbi kuita mambure.Kudhinda kunosanganisira akasiyana siyana emashizha-simbi ekugadzira maitiro ekugadzira, sekurova uchishandisa muchina muchina kana chidhindo chekutsikirira, kuvhara, embossing, kukotama, kupeta, uye kuita mari.Uku kunogona kunge kuri danho rimwe chete apo sitiroko yese yemuchina inoburitsa fomu inodiwa papepa resimbi chikamu, kana kuti inogona kuitika kuburikidza nematanho akatevedzana.Iyo nzira inowanzoitwa papepa simbi, asi inogonawo kushandiswa pane zvimwe zvinhu, senge polystyrene.Progressive dies inowanzo kudyiswa kubva pacoil yesimbi, coil reel yekusunungura coil kune inotwasanuka kuti ikwidze coil yozopinda mufeeder inosimudzira zvinhu muchina wobva wafa pakureba kwakafanotemerwa.Zvichienderana nechikamu chakaoma, nhamba yezviteshi mufa inogona kutsanangurwa.

Kutsika kunowanzoitwa pane inotonhora simbi sheet.Ona Forging yekugadzira simbi inopisa.

Simbi isina tsvina: SS304, SS304L, SS316, SS316L, SS303, SS630

Carbon simbi: 35CrMo, 42CrMo, ST-52, Ck45, alloy simbi;ST-37, S235JR, C20, C45, 1213, 12L14 carbon steel;

Brass alloy: C36000, C27400, C37000, CuZn36Pb3, CuZn39Pb1, CuZn39Pb2

Aluminium alloy: AlCu4Mg1, AlMg0.7Si, AlMg1SiCu, EN AW-2024, EN AW-6061, EN AW-6063A.

1. Kupeta - zvinhu zvakakanganiswa kana kukotama pamwe nemutsara wakatwasuka.

2. Flanging - zvinhu zvakakombama pamwe nemutsara wakakombama.

3. Embossing - zvinhu zvakatambanudzwa mukuora mwoyo kusina kudzika.Inoshandiswa kunyanya kuwedzera maitiro ekushongedza.

4. Kuvhara - chidimbu chinochekwa kubva papepa rezvinhu, kazhinji kuita blank for further processing.

5. Coining - pateni inomanikidzwa kana kusvinwa muzvinhu.Zvagara zvichishandiswa kugadzira mari.

6. Kudhirowa - nzvimbo yepasi isina chinhu inotambanudzwa kuita imwe chimiro kuburikidza neinodzorwa zvinhu zvinoyerera.

7. Kutambanudza - nzvimbo yepasi pechinhu chisina chinhu inowedzera nekukakavadzana, pasina kufamba kwemukati kwemucheto usina chinhu.Kazhinji inoshandiswa kugadzira yakatsetseka auto nhengo dzemuviri.

8. Ironing - zvinhu zvinosvinwa uye zvakaderedzwa muhupamhi pamwe chete nemadziro akareba.Inoshandiswa kumagaba echinwiwa uye ammunition cartridge kesi.

9. Kuderedza / Necking - inoshandiswa kuderedza zvishoma nezvishoma dhayamita yemagumo akazaruka emudziyo kana chubhu.

10. Curling - deforming zvinhu kuita tubular profile.Hinges yemasuo muenzaniso wakajairika.

11. Hemming - kupeta mupendero pairi kuwedzera ukobvu.Micheto yemagonhi emotokari inowanzovharirwa.

Kuboora nekucheka kunogonawo kuitwa mumichina yekutsikirira.Progressive stamping isanganiswa yenzira dziri pamusoro dzinoitwa neseti yemafa akatevedzana apo chidimbu chechinhu chinopfuura nhanho imwe panguva.

Kudzima zvikamu zvakadhindwa

Stamping process

Simbi inotonhora yekutsika zvikamu