CNC milling process

Numerical control (zvakare komputa nhamba yekudzora, uye inowanzodaidzwa kuti CNC) ndiko kuzvidzora kwekutonga kwemachining maturusi (senge madhiri, lathes, mill uye 3D printers) kuburikidza nekombuta.Muchina weCNC unobata chidimbu chechinhu (simbi, purasitiki, huni, ceramic, kana composite) kuti isangane nezvakatsanangurwa nekutevera kodhi yakarongwa rairo uye pasina manyorero anoshanda anodzora machining mashandiro.

Muchina weCNC chishandiso chinofambiswa nemota uye kazhinji chikuva chinofambiswa chine mota, izvo zvese zvinodzorwa nekombuta, zvinoenderana nemirairo yekupinza.Mirayiridzo inounzwa kumuchina weCNC muchimiro chechirongwa chakatevedzana chemirairo yekudzora muchina seG-code neM-code, yobva yaitwa.Chirongwa ichi chinogona kunyorwa nemunhu kana, kazhinji kazhinji, kugadzirwa negraphical computer-aid design (CAD) software uye/kana komputa inobatsira kugadzira (CAM) software.Muchiitiko che 3D printers, chikamu chichadhindwa "chakachekwa", mirairo (kana purogiramu) isati yagadzirwa.Maprinta e3D anoshandisawo G-Code.

CNC kunatsiridza kwakakura pamusoro peasiri e-machining ekombuta anofanirwa kudzorwa nemaoko (sekushandisa midziyo yakaita semavhiri emaoko kana marevheti) kana kudzorwa nemuchina nemadhiraivha epatani ekare (cams).Mumazuva ano CNC masisitimu, dhizaini yechikamu chemuchina uye chirongwa chayo chekugadzira chakanyanya otomatiki.Iyo chikamu chemechani zviyero zvinotsanangurwa uchishandisa CAD software uye zvino inoshandurirwa mukugadzira mirairo nekombuta-inobatsira kugadzira (CAM) software.Iwo anokonzeresa madhairekitori anoshandurwa (ne "post processor" software) kuita iwo chaiwo mirairo inodiwa kuti mumwe muchina uburitse chikamu uye wozoiswa mumuchina weCNC.

Sezvo chero chimwe chikamu chingada kushandiswa kwezvishandiso zvakasiyana-siyana - zvibooreso, masaha, nezvimwewo - michina yemazuva ano inowanzobatanidza maturusi akawanda kuita "sero" rimwe chete.Mune kumwe kuisirwa, akati wandei emakina akasiyana anoshandiswa ane wekunze controller uye vanhu kana marobhoti anoshanda anofambisa chikamu kubva muchina kuenda kumuchina.Chero zvazvingaitika, nhevedzano yematanho anodiwa kugadzira chero chikamu chakanyanya otomatiki uye chinoburitsa chikamu chinonyatsoenderana neiyo yekutanga CAD kudhirowa.

Kugaya inzira yekucheka inoshandisa milling cutter kubvisa zvinhu kubva pamusoro pechigamba chebasa.Chigayo chekucheka chishandiso chinotenderera, kazhinji chine mapoinzi akawanda ekucheka.Kusiyana nekuchera, uko chishandiso chinofambiswa mberi neakisi yayo yekutenderera, mucheki mukugaya anowanzo fambiswa perpendicular kune axis yayo kuitira kuti kucheka kunoitika padenderedzwa reanocheka.Sezvo mucheki wekucheka achipinda muchikamu chebasa, mitsara yekucheka (nyere kana mazino) emudziyo wacho anoramba achicheka mukati uye achibuda kubva pane zvinyorwa, achiveura machipisi (swarf) kubva pachigadziro chebasa nekupfuura imwe neimwe.Kucheka chiito ndiko kugera deformation;zvinhu zvinosundirwa kubva pachikamu chebasa muzvikamu zvidiki zvinorembera pamwechete kusvika pamwero mukuru kana mudiki (zvichienderana nezvakagadzirwa) kugadzira machipisi.Izvi zvinoita kuti simbi ichekwe yakati siyanei (mumakanika ayo) kubva mukuchekeresa zvinhu zvakapfava nebadza.

Kugaya kunobvisa zvinhu nekuita akawanda akaparadzana, madiki kucheka.Izvi zvinopedzwa nekushandisa mucheki ane mazino akawanda, kupuruzira mucheki nekumhanya kukuru, kana kufambisira mberi zvinhu kuburikidza nemucheki zvishoma nezvishoma;kazhinji kazhinji mubatanidzwa weidzi nzira nhatu.[2]Mamhanyiro nemafeed anoshandiswa anosiyana-siyana kuti aenderane nemusanganiswa wezvakasiyana.Kumhanya kunoita chidimbu kuburikidza nemucheki kunonzi feed rate, kana kungodyisa;inowanzoyerwa sedaro panguva (mainji paminiti [mu/min kana ipm] kana mamirimita paminiti [mm/min]), kunyange zvazvo chinhambwe pabhindauko kana kuti pazino rokucheka rinoshandiswawo dzimwe nguva.

Kune makirasi maviri makuru ekugadzira milling:

1.Mukugaya kwechiso, chiito chekucheka chinoitika kunyanya pamakona ekupedzisira ekucheka kwekucheka.Kugaya kwechiso kunoshandiswa kucheka nzvimbo dzakati sandara (zviso) kuita chidimbu chebasa, kana kucheka maburi akadzika-pasi.

2.Muchigayo cheperipheral, chiito chekucheka chinoitika kunyanya pamwe nekutenderera kwemucheki, kuitira kuti chikamu chemuchinjikwa chemilled surface chinopera kugamuchira chimiro chekucheka.Muchiitiko ichi mashizha emucheki anogona kuonekwa seanobvisa zvinhu kubva pakushanda.Peripheral milling yakanyatsokodzera kucheka kwakadzika slots, shinda, uye giya mazino.

| CNC muchina | Tsanangudzo |

| Chigayo | Tinoshandura zvirongwa zvine manhamba chaiwo uye mavara kufambisa spindle (kana workpiece) kunzvimbo dzakasiyana siyana nekudzika.Vazhinji vanoshandisa G-code.Mabasa anosanganisira: kugaya kumeso, kugaya pamapfudzi, kubaya, kudhiraivha uye zvimwe zvinopa kutendeuka.Nhasi, CNC zvigayo zvinogona kuva 3 kusvika 6 mbezo.Mazhinji CNC zvigayo zvinoda kuisa workpiece pairi kana mavari uye inofanira kunge yakakura senge workpiece, asi mitsva ye3-axis michina iri kugadzirwa iyo idiki kwazvo. |

| Lathe | Inocheka workpieces pavanenge vachitenderedzwa.Inoita kukurumidza, kuchekwa chaiko, kazhinji uchishandisa indexable maturusi uye madhiri.Inoshanda pamapurogiramu akaomarara akagadzirirwa kugadzira zvikamu zvingave zvisingaite kugadzira pamawoko lathes.Zvakafanana kudzora zvirevo kune CNC zvigayo uye anogona kazhinji kuverenga G-kodhi.Kazhinji iva nematemo maviri (X uye Z), asi mhando itsva dzine matemo akawanda, zvichiita kuti mamwe mabasa epamusoro agadziriswe. |

| Plasma cutter | Inosanganisira kucheka zvinhu uchishandisa plasma torch.Inowanzoshandiswa kucheka simbi uye mamwe masimbi, asi inogona kushandiswa pane zvakasiyana-siyana zvezvinhu.Mukuita uku, gasi (semhepo yakamanikidzwa) inofuridzirwa nekumhanya kukuru kubva mumuromo;panguva imwecheteyo, arc yemagetsi inoumbwa kuburikidza neiyo gasi kubva pamuromo kusvika kumusoro iri kuchekwa, kushandura imwe yegasi iyo ku plasma.Plasma inopisa zvakakwana kunyungudusa zvinhu zviri kuchekwa uye inofamba zvakaringana kuti ifuridzire simbi yakanyungudutswa kubva pakachekwa. |

| Electric discharge machining | (EDM), inozivikanwawo se spark machining, spark eroding, kupisa, kufa kunyura, kana kunyura kwewaya, inzira yekugadzira umo chimiro chinodiwa chinowanikwa uchishandisa kubuda kwemagetsi (sparks).Material inobviswa kubva paworkpiece neyakatevedzana inokurumidza kudzokororwa ikozvino kubuda pakati pema electrode maviri, akaparadzaniswa nedielectric fluid uye pasi pemagetsi emagetsi.Imwe yemagetsi inonzi electrode yekushandisa, kana kungoti "chishandiso" kana "electrode," nepo imwe ichinzi "workpiece electrode", kana "workpiece". |

| Multi-spindle muchina | Rudzi rwe screw machine inoshandiswa mukugadzirwa kwehuwandu.Inofungidzirwa kuve inoshanda zvakanyanya nekuwedzera kugadzirwa kuburikidza neautomation.Inogona kunyatsocheka zvinhu kuita zvidimbu zvidiki panguva imwe chete uchishandisa zvakasiyana-siyana seti yekushandisa.Multi-spindle machines ine akawanda maspindle padhiramu inotenderera paakisi yakachinjika kana kuti yakatwasuka.Ngoma iyi ine musoro wekuboorera uyo unosanganisira zvirukwa zvinoverengeka zvakaiswa pamabhora ebhora uye zvichifambiswa nemagiya.Kune marudzi maviri ezvinamatidzwa zveiyi misoro yekuboora, inogadziriswa kana kuchinjika, zvichienderana nekuti chinhambwe chepakati chekuchera spindle chinoda kusiyanisa. |

| Wire EDM | Iyo inozivikanwawo sewaya yekucheka EDM, waya inopisa EDM, kana yekufambisa waya EDM, iyi nzira inoshandisa spark erosion kumashini kana kubvisa zvinhu kubva kune chero magetsi conductive zvinhu, uchishandisa inofamba waya electrode.Iyo electrode yewaya kazhinji ine ndarira- kana zinc-yakavharwa nendarira zvinhu.Wire EDM inobvumira pedyo ne90-degree makona uye inoshandisa kudzvinyirira kuduku pane zvinhu.Sezvo waya yakanyungudutswa mukuita uku, waya EDM muchina unodyisa waya nyowani kubva kune spool uchicheka waya yakashandiswa nekuisiya mubhini kuti idzokororwe. |

| Sinker EDM | Iyo inonziwo cavity type EDM kana vhoriyamu EDM, inonyura EDM ine electrode uye workpiece yakanyudzwa mumafuta kana imwe dielectric fluid.Iyo electrode uye workpiece yakabatanidzwa kune yakakodzera simba rekupa, iyo inoburitsa simba remagetsi pakati pezvikamu zviviri.Sezvo electrode inoswedera kune workpiece, dielectric breakdown inoitika mumvura inogadzira plasma chiteshi uye diki spark kusvetuka.Kugadzirwa kunofa uye molds inowanzogadzirwa ne siker EDM.Zvimwe zvinhu, zvakaita semidziyo yakapfava yeferrite uye epoxy-rich bonded magineti zvinhu hazvienderane ne sinker EDM sezvo zvisiri zvemagetsi.[6] |

| Mvura jet cutter | Iyo inozivikanwawo se "waterjet", chishandiso chinokwanisa kutsemura kuita simbi kana zvimwe zvinhu (se granite) nekushandisa jeti remvura riri pahigh velocity uye pressure, kana musanganiswa wemvura nechinhu chinoputika, sejecha.Inowanzo shandiswa panguva yekugadzira kana kugadzirwa kwezvikamu zvemichina nemimwe michina.Waterjet ndiyo nzira inosarudzika kana zvinhu zviri kuchekwa zvichinzwa nekupisa kwakanyanya kunogadzirwa nedzimwe nzira.Yakawana zvikumbiro muhuwandu hwakasiyana-siyana hwemaindasitiri kubva kumigodhi kuenda kune aerospace uko inoshandiswa kuita sekucheka, kuumba, kuveza, uye kugadzirisa zvakare. |

CNC kuchera

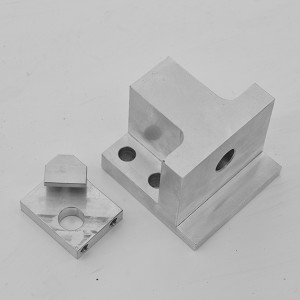

zvikamu

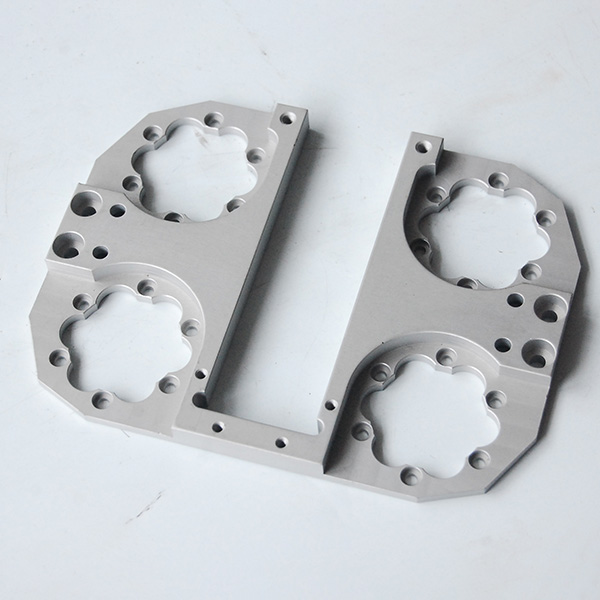

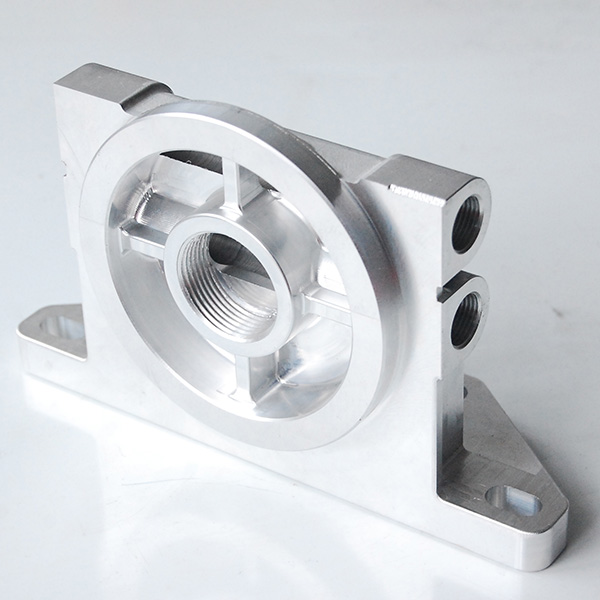

CNC yakagadzirwa

zvikamu zvealuminium

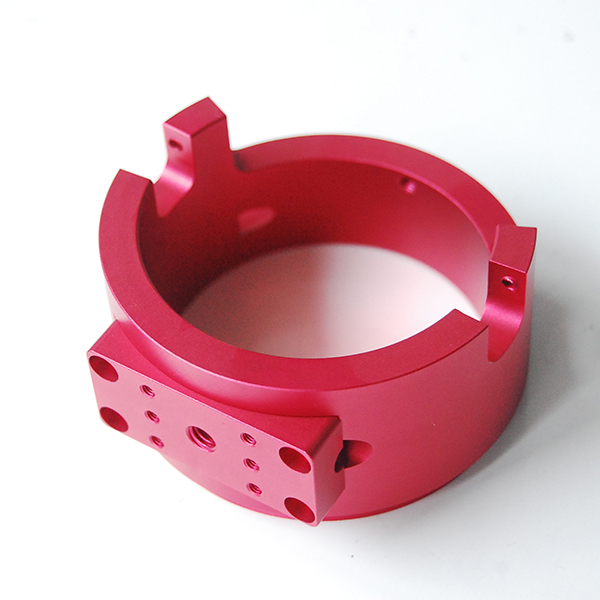

CNC machining

zvikamu zvakakombama

CNC machining zvikamu

pamwe anodizing

High nemazvo

cnc zvikamu

Precision aluminium casting

ine machined uye anodized

Precision cast aluminum

with machined

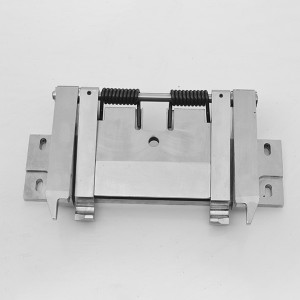

Simbi cnc

machining zvikamu